TECHNOLOGIES

Aiming to make products that satisfy customer needs

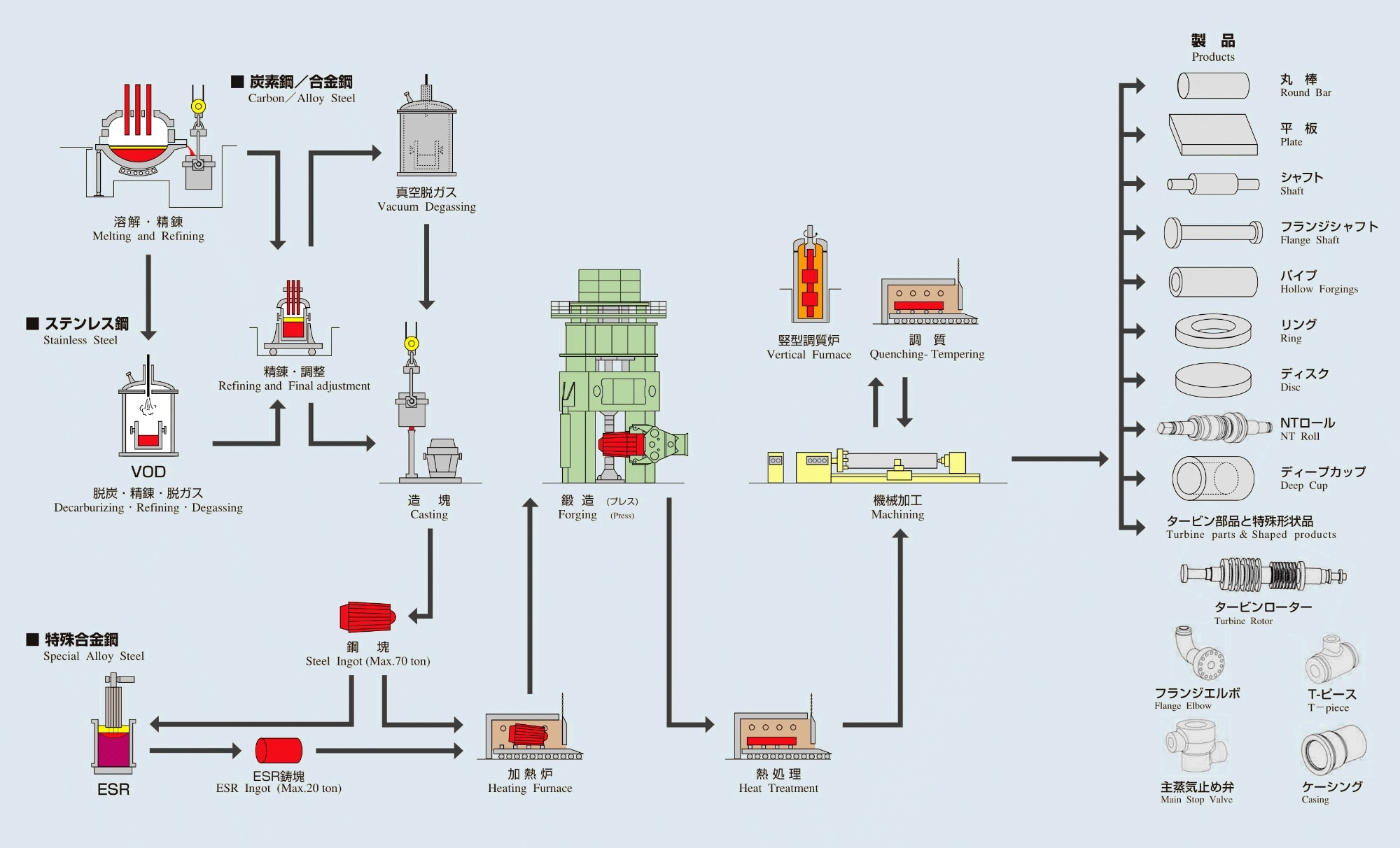

In order to flexibly respond to ever-changing global needs, we at Pacific Steel Mfg. conduct various simulations, experiments, and product development using the latest equipment.

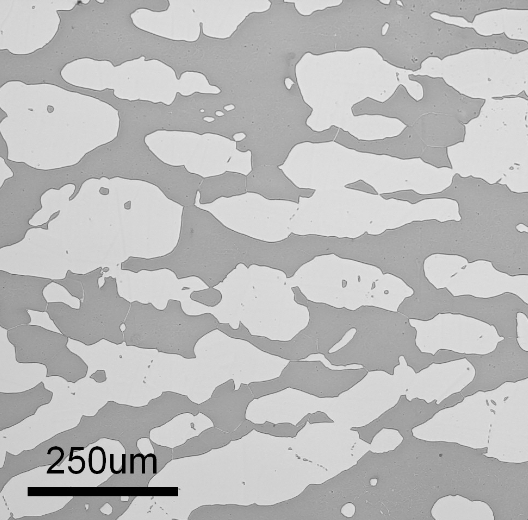

ミクロ組織・フェライト率

ミクロ組織・フェライト率

(フェライト率:46.3±4.3)

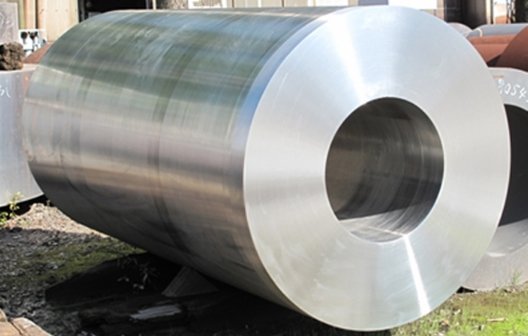

F55 pump casings(製造試験材)

F55 pump casings(製造試験材)

Since then, iron, as a symbol of civilization, has been used in a wide variety of forms, such as for farm implements and household tools in addition to weapons. After the Industrial Revolution, iron and steel became more and more important - so much so that there was a saying that the iron and steel industry 'makes' a country. Production of iron and steel has dramatically increased, and they now are indispensable materials in our lives.