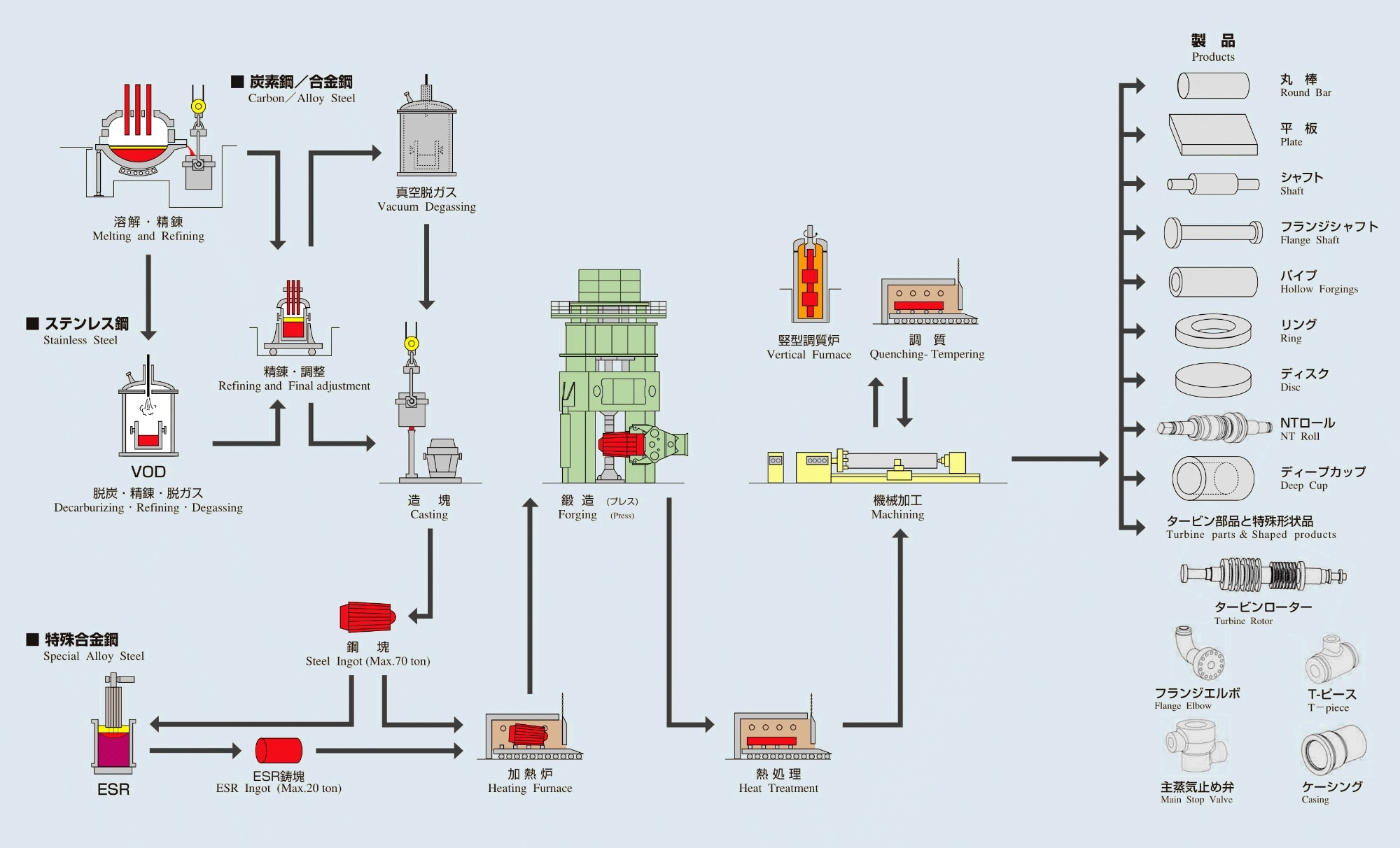

FACILITIES

From steelmaking to forging and machining

We are one of the few companies in Japan that have this kind of fully-integrated production capability, and achieve the quality to satisfy our customers' needs.

Basic data (shape, weight, intended use, etc.) are confirmed. Drawings and other related documents are also requested in advance.

Details (material, delivery schedule, etc.) are worked out based on the drawings and other documents.

delivery

The product is rustproofed, packed, and shipped.

Steelmaking refers to the process of melting and solidifying steel.

Forging is a technology in which the material is given its general shape.

Heat treatment modifies the material properties of steel.

Machining gives the final shape to the product.

We take all possible measures to manage product quality, such as the heat stability test (which determines the deflection of products by applying a temperature difference of more than 500 ℃), the tensile test to evaluate strength, and the impact test to evaluate tenacity.

-

Heat stability testing machine

Heat stability testing machine -

Impact tester

Impact tester -

X-ray residual stress analyzer

X-ray residual stress analyzer