優れた技術と品質により

自然にやさしく

社会に貢献する

Gentle with Nature and Contribute Toward the Social Progress

by Fine Technology and Quality

PRODUCTS 製品情報

お客様のニーズに

的確に応えられる製品開発力

OUR

ADVANTAGE

技術案内

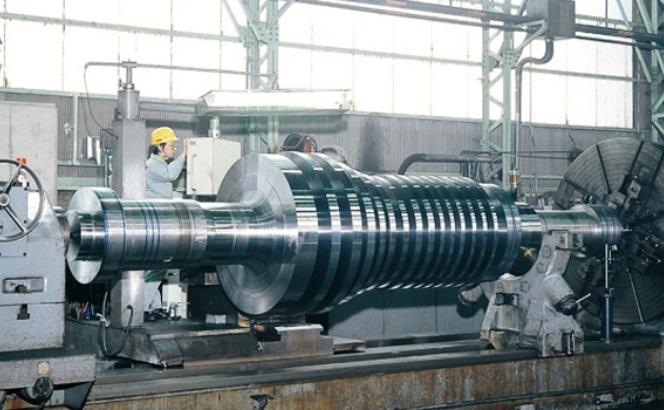

大平洋製鋼は、日々変化する世の中のニーズに柔軟に対応するため、最新の機器を使い様々なシミュレーションや研究試験、製品開発を行っています。

COMPANY 企業情報

RECRUIT 採用情報

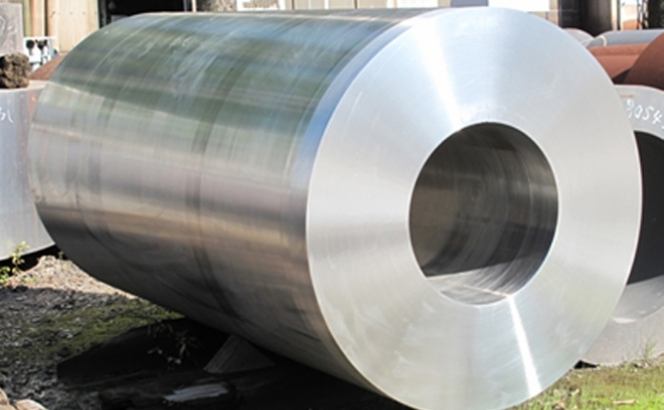

私達は、鉄の溶解から製品の加工までを一貫して行う、世界的にも数少ない鍛鋼品一貫生産メーカーです。

「ものづくり」をしたい方、鉄鋼業や社会インフラに興味がある方、鋼のプロになりたい方、富山で働きたい方、あなたのエントリーをお待ちしています!